Intake Pits & Intake Systems

With the ever-increasing outputs of modern day combine harvesters, larger trailers and lorries, it is important to have a fast and efficient intake system to avoid a ‘bottle neck’ on any farm or commercial plant. A good intake can save a lot of time and costs with extra drivers and trailers. Here at Danagri-3S Ltd, we offer three different types of Intake to suit different needs, these are:

- Below Floor – Our Dry Pit range

- Level Floor

- Above Floor systems with tipping hoppers.

The handling equipment to take the grain away can range from 20 – 1000tph! Each project is different, but as you will see from the information and pictures below, we have the equipment and experience to help solve your requirements.

Grain Auger Hoppers

Grain Auger hopper available to fit 8" and 10" auger pipes.

The yellow grain auger hoppers are ideal for efficient unloading of grain. Made from lightweight, UV-resistant and flexible plastic, they withstand most accidental impacts, while their bright colour makes the visible when in use. Available in three sizes they secure with straps to the auger tube:

- Small: fits augers 4"- 6" and weighs 8 lbs.

- Regular: fits augers 6" - 7" - "8 and weighs 17 lbs.

- Big Round: fits augers 10" and above and weighs 31 lbs.

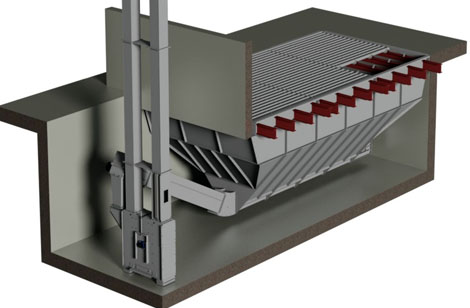

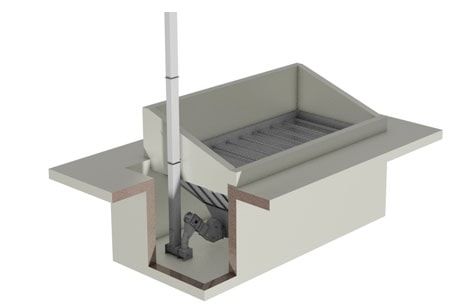

Danagri-Jema Self emptying Dry Pit

Cutaway of Jema Drive Over Dry PitShow Full Screen

Cutaway of Jema Drive Over Dry PitShow Full Screen Walk over Dry PitShow Full Screen

Walk over Dry PitShow Full Screen Drive over Dry Pit with side and rear extension panelsShow Full Screen

Drive over Dry Pit with side and rear extension panelsShow Full Screen Drive over dry pit and buildingShow Full Screen

Drive over dry pit and buildingShow Full Screen Self emptyingShow Full Screen

Self emptyingShow Full Screen Extra capacity above floorShow Full Screen

Extra capacity above floorShow Full Screen Cutaway of Jema walk over Dry PitShow Full Screen

Cutaway of Jema walk over Dry PitShow Full Screen

- Speeds up intake – Dump & go!

- Suspended heavy duty steel hopper

- Modular design – simple assembly

- Walk over or Drive over versions

- 3m wide and many different lengths

- Optimal protection against water

- Easy access for servicing

- Optional dust extraction systems

Level Floor Intake systems

50 tph system on farmShow Full Screen

50 tph system on farmShow Full Screen 60 tonne ‘wet grain’ store for drierShow Full Screen

60 tonne ‘wet grain’ store for drierShow Full Screen 100 & 150 tonne intake with 30 degree bend to drive headShow Full Screen

100 & 150 tonne intake with 30 degree bend to drive headShow Full Screen 12m long intake with sloping retaining wall behindShow Full Screen

12m long intake with sloping retaining wall behindShow Full Screen Level floor bunker feeding drierShow Full Screen

Level floor bunker feeding drierShow Full Screen Intake sunk by 1.0m in floor with end plate for service accessShow Full Screen

Intake sunk by 1.0m in floor with end plate for service accessShow Full Screen Bunker with level floor conveyor feeding silosShow Full Screen

Bunker with level floor conveyor feeding silosShow Full Screen

- Capacities from 25 – 1000tph

- Top of conveyor is level with concrete floor

- Conveyors can be up to 28m long

- Reliable gear motor drives

- Galvanized casings

- Horizontal, angled or 90 degree bends

- Agricultural and commercial options

- Heavy duty chains

Above floor Tipping Hopper Intake systems

3m Intake hopper with extension sidesShow Full Screen

3m Intake hopper with extension sidesShow Full Screen 4m hopper with extension sidesShow Full Screen

4m hopper with extension sidesShow Full Screen 1m hopper with hinged steel lidShow Full Screen

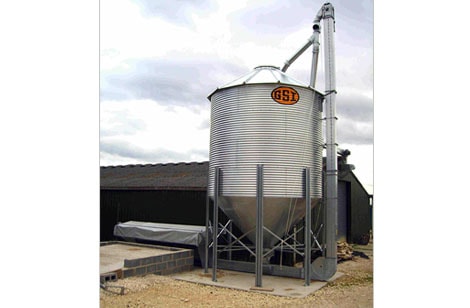

1m hopper with hinged steel lidShow Full Screen 4m hopper with tarpaulin top feeding siloShow Full Screen

4m hopper with tarpaulin top feeding siloShow Full Screen 3m standard Intake hopper with T40 elevatorShow Full Screen

3m standard Intake hopper with T40 elevatorShow Full Screen 4m hopper with extension sides and tarpaulinShow Full Screen

4m hopper with extension sides and tarpaulinShow Full Screen 4m hopper with extension sides and steel lidShow Full Screen

4m hopper with extension sides and steel lidShow Full Screen

- Self-emptying hoppers

- Lengths from 1.0m – 10m

- Optional extension side and backs

- Optional steel or tarpaulin covers

- Modular galvanized sections

- Can be used with chain conveyors or augers

- Easy access for servicing conveyors

- Popular for wood pellets as well as all grains