Servicing

Danagri-3S import, distribute, service and install equipment for many key names in the agricultural sector such as GSI Silos, SKIOLD, Cormall, Hutchinson, DMC, FFI Dryers, Jema Elevators & Conveyors, BM Silo, Lokkers, Hampshire Feeding Systems to name a few.

Based in the Midlands we stock, dispatch and attend to call outs across the UK. We hold significant amounts of spare parts to back up our main product lines.

X

Servicing GSI & Farm Fans grain driersShow Full Screen

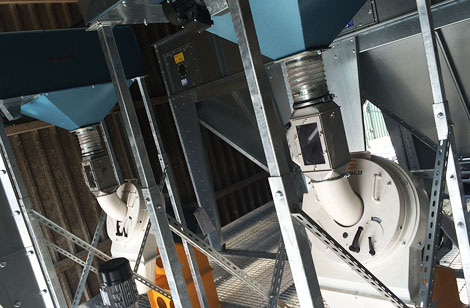

Servicing GSI & Farm Fans grain driersShow Full Screen Service of conveyors and elevator plantShow Full Screen

Service of conveyors and elevator plantShow Full Screen Service of milling machinesShow Full Screen

Service of milling machinesShow Full Screen Service of feed mill plantsShow Full Screen

Service of feed mill plantsShow Full Screen Machining and balancing of HFS pump partsShow Full Screen

Machining and balancing of HFS pump partsShow Full Screen Fully equipped service vansShow Full Screen

Fully equipped service vansShow Full Screen Assembly and service of HFS pump partsShow Full Screen

Assembly and service of HFS pump partsShow Full Screen

- We're here for you, when you need us the most!

- Authorised, trained service engineers on call 365

- We repair and service Mills, Dryers, Straw Plant, Silos, Conveyors, Heaters, Filters, Augers, Feed Systems and many more

Grain Dryer Servicing

Danagri-3S specialises in servicing and repair of grain dryers, with particular expertise in GSI and Farm Fans systems. Our thorough inspection ensures your equipment performs at its best during harvest.

What’s Included in a Grain Dryer Inspection?

- Visual Inspection for signs of wear, corrosion, or damage to key components such as burner assemblies, fans, belts, and augers.

- Electrical System Check of control panels, sensors, wiring, and safety switches to ensure safe and efficient operation.

- Burner and Fuel System Assessment with cleaning and calibration of burners, check of fuel lines and filters for blockages or leaks.

- Airflow and Ventilation Review to make sure fans and ducts are clear and functioning correctly to maintain consistent drying performance.

- Mechanical Component Testing of motors, bearings, and drive systems.

- Calibration and Performance check of temperature settings, moisture sensors, and throughput rates to optimise drying efficiency.

Benefits of Regular Servicing

- Improved Reliability – Prevent unexpected breakdowns during peak harvest periods, reducing costly delays.

- Enhanced Efficiency – Ensure your dryer operates at optimal performance, saving energy and reducing fuel costs.

- Extended Equipment Life – Routine maintenance helps protect your investment and prolong the lifespan of your machinery.

- Better Grain Quality – Consistent drying reduces spoilage and improves storage outcomes, protecting your yield.

- Compliance and Safety – Regular checks help meet safety standards and reduce fire risk associated with grain drying operations.