In-Bin Grain Drying and Stirrer Machines

Drying grain in-bin can be a significantly lower investment compared to a grain drier, it is a cheaper form of drying and gives you up to 1500 tonnes of storage too. This is achieved because one bin can be used for storage AND drying at the same time.

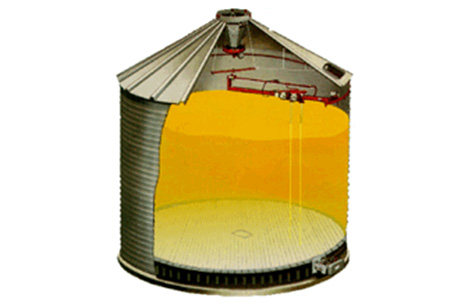

Dependent upon the silo diameter, a GSI/DMC stirrer will usually move all of the grain at least 3 times in a 24 hour period. This stirrer auger moves gently through the grain and helps give much better air flow and use of heat throughout the silo. Using our temperature control system you can easily take out over 2% of moisture per day from the whole of the silo on feed wheats. It is a simple process to use and our customer consistently tell us it is the cheapest way of drying grain.

Systems

X

500 tonne stirrer silos - OxfordshireShow Full Screen

500 tonne stirrer silos - OxfordshireShow Full Screen 375 tonne stirrer silo - LancashireShow Full Screen

375 tonne stirrer silo - LancashireShow Full Screen Cross section of stirrer siloShow Full Screen

Cross section of stirrer siloShow Full Screen

- 1500 tonne stirred – 60’ silo

- 1200 tonne stirred – 54’ silo

- 1000 tonne stirred – 48’ silo

- 700 tonne stirred – 42’ silo

- 500 tonne stirred – 36’ silo

- 375 tonne stirred – 30’ silo

Fans & Heaters

X

25hp fan & heater - Bedfordshire Show Full Screen

25hp fan & heater - Bedfordshire Show Full Screen 20hp fan & heater - NottinghamshireShow Full Screen

20hp fan & heater - NottinghamshireShow Full Screen 25hp fan & heater – EssexShow Full Screen

25hp fan & heater – EssexShow Full Screen

- Centrifugal fans for greater efficiency

- Range from 5 -50hp

- Vapour gas heaters with modulating valve

- Quiet & reliable

Stirrer machines

X

Triple auger stirrer in a new 1000t Grain SiloShow Full Screen

Triple auger stirrer in a new 1000t Grain SiloShow Full Screen Triple Auger stirrerShow Full Screen

Triple Auger stirrerShow Full Screen Double auger stirrerShow Full Screen

Double auger stirrerShow Full Screen

- Stirring system for Wheat, Barley, OSR, Oats, etc.

- Ensures consistent air flow for even moisture content.

- For silos up to 60’ (18m) diameter

- Efficient use of heat

- Cheapest cost per tonne for drying

- Manufactured for over 50 years

Control Panels

X

Control panel starters and temperature controllersShow Full Screen

Control panel starters and temperature controllersShow Full Screen Control panel mimicShow Full Screen

Control panel mimicShow Full Screen Outdoor panel casingShow Full Screen

Outdoor panel casingShow Full Screen

- UK manufacture

- Built to individual needs and specifications

- Temperature selector for different crops

- Modulating temperature controller

- Mimic display to show all controls

- Hours run indicator