Elevators & Conveyors

Danagri-3S Ltd are UK agents for Jema Agro A/S from Denmark. Jema started production of chain elevators back in 1945 and now offer an extensive range of intake conveyors, belt & bucket elevators, chain & flight conveyors, belt conveyors, automated floor store equipment and accessories for transporting grain, granulates, meals and other bulk materials. All machines are galvanised, of modular construction and are driven by reliable direct drive motors.

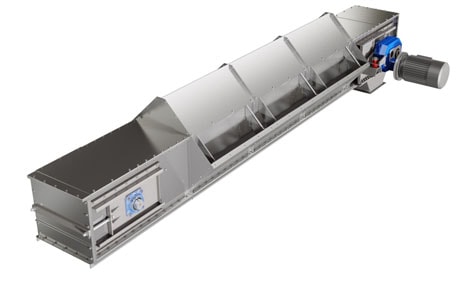

Intake Conveyors

Intake Conveyor with horizontal powerheadShow Full Screen

Intake Conveyor with horizontal powerheadShow Full Screen Sunken intakeShow Full Screen

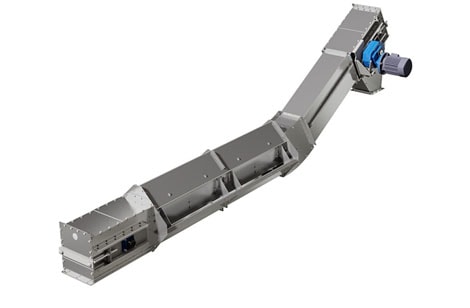

Sunken intakeShow Full Screen Intake with 30 degree bendShow Full Screen

Intake with 30 degree bendShow Full Screen Intake with 90 degree bendShow Full Screen

Intake with 90 degree bendShow Full Screen Intake with side auger feedShow Full Screen

Intake with side auger feedShow Full Screen

- Capacities of 25 – 225tph

- Farm and commercial models

- Heavy duty galvanized steel

- Modular design – simple assembly

- 30, 45 and 90 degree bends available

- Self-emptying design

- Intake lengths up to 20m

- Side auger delivery options

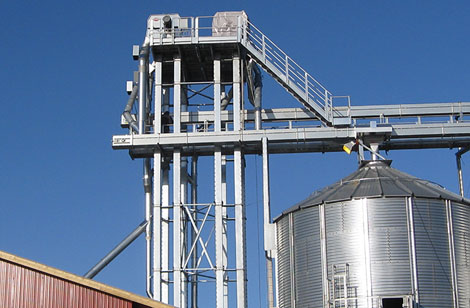

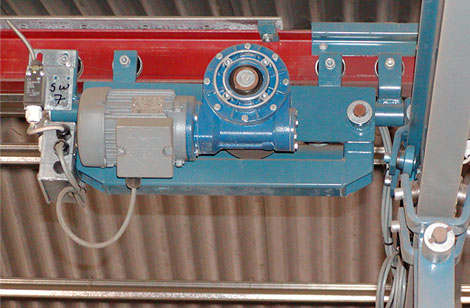

Belt & Bucket Elevators

60tph Elevators filling silosShow Full Screen

60tph Elevators filling silosShow Full Screen 100tph Elevator with service platform and access ladderShow Full Screen

100tph Elevator with service platform and access ladderShow Full Screen Installing 2x 150tph ElevatorsShow Full Screen

Installing 2x 150tph ElevatorsShow Full Screen 100tph elevator feeding floor store conveyors Show Full Screen

100tph elevator feeding floor store conveyors Show Full Screen Elevator with gear motor driveShow Full Screen

Elevator with gear motor driveShow Full Screen 150tph Elevator feeding silosShow Full Screen

150tph Elevator feeding silosShow Full Screen

- 6 models, capacities from 5 – 225tph

- Farm and commercial models

- Modular design – simple assembly

- Standard or oil resistant belt

- Feeds into down leg or up leg

- Back stop as standard

- Standard heights from 2 – 28m

- Wide range of accessories

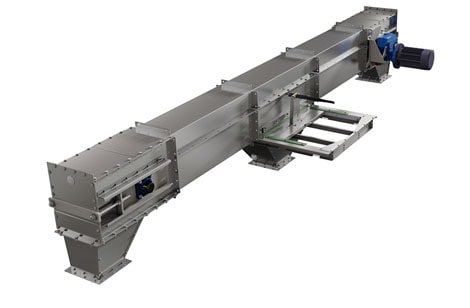

Chain & Flight conveyors

100tph filling silosShow Full Screen

100tph filling silosShow Full Screen 60tph filling silosShow Full Screen

60tph filling silosShow Full Screen Conveyor with intermediate outletShow Full Screen

Conveyor with intermediate outletShow Full Screen 150 tonne conveyor feeding elevatorShow Full Screen

150 tonne conveyor feeding elevatorShow Full Screen 150tph system over silosShow Full Screen

150tph system over silosShow Full Screen 100tph coming from mobile drier to floor storeShow Full Screen

100tph coming from mobile drier to floor storeShow Full Screen

- 6 models, capacities from 20 – 225tph

- Farm and commercial models

- Modular design – simple assembly

- Models T44/45 can be used at any angle

- Models T49/57/300 up to 30 degrees

- Intermediate outlets, electric or manual

- Rubber or plastic carriers

- Optional 8mm PEHD wear plate

Chain Elevators

Chain elevator with hopperShow Full Screen

Chain elevator with hopperShow Full Screen Angled and vertical chain elevatorsShow Full Screen

Angled and vertical chain elevatorsShow Full Screen Elevator with 90 degree bendShow Full Screen

Elevator with 90 degree bendShow Full Screen Elevator for filling silo with 55 degree bendShow Full Screen

Elevator for filling silo with 55 degree bendShow Full Screen Chain Elevator feeding drierShow Full Screen

Chain Elevator feeding drierShow Full Screen

- 2 models, capacities from 20 – 60tph

- Can combine vertical and horizontal transport

- 45, 55 or 90 degree bends available

- Can be used at any angle

- Modular design – simple assembly

- Rubber carriers for gentle transportation

- Side delivery augers can be fitted

- For meals, pellets, grains, granulates

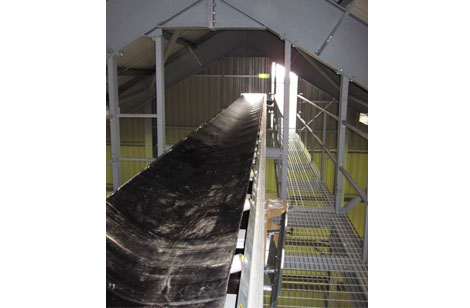

Belt Conveyors

100tph belt conveyor with tripper carriageShow Full Screen

100tph belt conveyor with tripper carriageShow Full Screen Tripper carriageShow Full Screen

Tripper carriageShow Full Screen Belt conveyor showing rollers, inlet & tripperShow Full Screen

Belt conveyor showing rollers, inlet & tripperShow Full Screen Belt conveyors with bottom coverShow Full Screen

Belt conveyors with bottom coverShow Full Screen 150tph belt conveyor and catwalkShow Full Screen

150tph belt conveyor and catwalkShow Full Screen 150tph tripper carriageShow Full Screen

150tph tripper carriageShow Full Screen 60tph belt conveyor & tripper carriageShow Full Screen

60tph belt conveyor & tripper carriageShow Full Screen

Belt conveyors are the modern way of filling a floor store, they offer a gentle handling as goods are carried instead of being pushed, you can move higher capacities with less power and the tripper carriage means you can offload all the way along the belt and get more product in your building. Ideal for automatically filling a store after your drier.

- 5 models, capacities from 25 – 300ph

- Troughed profile in conveying section

- Supports rollers every 0.5m

- Adjusters in both drive and end sections

- Smooth and quiet operation

- Modular design – simple assembly

- Optional electric winch for tripper

- Large range of options

Floor Store Automated Filling

Floor store systemShow Full Screen

Floor store systemShow Full Screen Level filling of storeShow Full Screen

Level filling of storeShow Full Screen Flat store conveyors and stirrerShow Full Screen

Flat store conveyors and stirrerShow Full Screen Flat store conveyor systemShow Full Screen

Flat store conveyor systemShow Full Screen Electric winchShow Full Screen

Electric winchShow Full Screen Central conveyor and side to side conveyorShow Full Screen

Central conveyor and side to side conveyorShow Full Screen Level filling of storeShow Full Screen

Level filling of storeShow Full Screen

Jema are Europe’s market leader in floor store automated filling equipment, their first systems in the UK were installed as long ago as 1980. The systems allow you to level fill all across the store or in selected bunkered areas.

The main central belt conveyor feeds off to an auger or reversible belt conveyor underneath which distributes side to side across the store. Options include sonar depth control, electric winches, suspension brackets and everything to make a system fully automatic.

- 3 models, capacities from 50 – 150ph

- Fills stores to their optimum capacity

- Two versions of cross conveyor, auger or belt

- Can be used with full width building or split building with air tunnel

- System allows for layer drying

- System allows better air distribution through grain

- Range of control panels with different features

- Auto start of fans, temp sensors, alarms & reports

- Internet connection for PC, tablet or mobile phone