Mills

On-Farm Milling Benefits

On-farm milling is a way to take control of feed production, reduce costs, and improve livestock performance. By processing grains directly on-site, farmers can tailor feed to the specific nutritional needs of their animals while avoiding the expense and variability of commercial feed.

- Reduce feed costs, which can account for up to 70% of total livestock production expenses.

- Improve feed quality and consistency, enhancing animal health and performance.

- Increase operational independence, with full control over ingredient sourcing and feed formulation.

- Adapt quickly to changing nutritional needs, market conditions, or ingredient availability.

Whether feeding poultry, pigs, or ruminants, understanding the operational strengths and limitations of each milling system is essential for building a resilient and efficient feed infrastructure.

Milling Systems

- Hammer mills: Versatile and ideal for producing fine particles, especially for poultry and pig feed. They can handle a wide range of materials, including fibrous and oily inputs, but tend to consume more energy and generate more dust.

- Roller mills: Deliver consistent particle sizes with lower energy consumption, making them well-suited for cattle feed and large-scale operations. Their precision and efficiency can lead to significant savings over time.

- Disc mills: Offer uniform grinding with adjustable settings, making them ideal for farms needing flexibility across different feed types. They are particularly effective for dry grains and pulses and are known for their energy efficiency and low noise output.

Roller Mills

Sipma Roller MillShow Full Screen

Sipma Roller MillShow Full Screen Magnet cartridge protects crusher mechanism from unwanted metal or stones.Show Full Screen

Magnet cartridge protects crusher mechanism from unwanted metal or stones.Show Full Screen Body design ensures tightness of the crusher and enables precise assembly of working elements.Show Full Screen

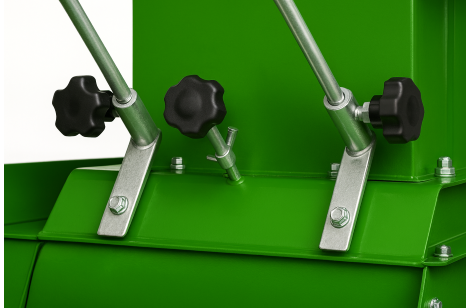

Body design ensures tightness of the crusher and enables precise assembly of working elements.Show Full Screen Grain dosing adjustment of charged grain to the working gap size.Show Full Screen

Grain dosing adjustment of charged grain to the working gap size.Show Full Screen V Belt SystemShow Full Screen

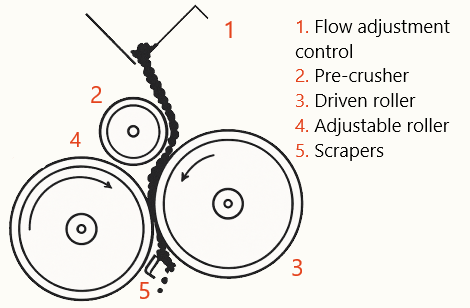

V Belt SystemShow Full Screen Three roller system pre-crushes feedShow Full Screen

Three roller system pre-crushes feedShow Full Screen Flow adjustment controlsShow Full Screen

Flow adjustment controlsShow Full Screen Grain before rolling with a Sipma millShow Full Screen

Grain before rolling with a Sipma millShow Full Screen Grain after rolling with Sipma millShow Full Screen

Grain after rolling with Sipma millShow Full Screen

Unlock Superior Feed Processing with Sipma Roller Mills

Roller mills offer a robust, efficient, and reliable way to process grains for your livestock. Engineered with precision, and built to last, they are the ideal solution for farmers seeking to optimize feed quality and reduce costs.

Experience the Sipma Advantage:

SKIOLD Disc Mills

SK2500 Disc MillShow Full Screen

SK2500 Disc MillShow Full Screen SK2500 with magnetShow Full Screen

SK2500 with magnetShow Full Screen SK5000 Automatic Disc MillShow Full Screen

SK5000 Automatic Disc MillShow Full Screen SK5000 Manual Mills with magnetsShow Full Screen

SK5000 Manual Mills with magnetsShow Full Screen SK10 Disc Mill with feed screwShow Full Screen

SK10 Disc Mill with feed screwShow Full Screen SK10 Disc Mill with magnetShow Full Screen

SK10 Disc Mill with magnetShow Full Screen 2x SK780 Disc Mills with feed screwsShow Full Screen

2x SK780 Disc Mills with feed screwsShow Full Screen SK780 Commercial Disc Mill Show Full Screen

SK780 Commercial Disc Mill Show Full Screen

SKIOLD Disc mills are based on award-winning technology, proven through the thousands of machines in operation worldwide since their launch in 2000. This grinding equipment is essential in feed production for livestock, particularly poultry and pigs, but also cattle and other ruminants. It's designed to mill various raw materials, including dry grains, pulses, and pellets up to 12mm in diameter. One of the key advantages of SKIOLD Disc mills is the ability to vary the grinding degree during operation, thereby optimizing feed structure for different animal groups

SKIOLD DM6 Hammer Mills

2x SKIOLD DM-6 Mills with U-trough augerShow Full Screen

2x SKIOLD DM-6 Mills with U-trough augerShow Full Screen SKIOLD DM-6 with adjustable legsShow Full Screen

SKIOLD DM-6 with adjustable legsShow Full Screen DM-6 Mill with magnetShow Full Screen

DM-6 Mill with magnetShow Full Screen Material gravity fed through mill.Show Full Screen

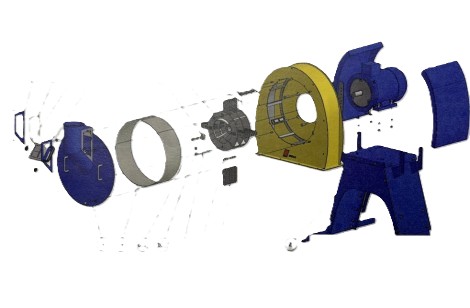

Material gravity fed through mill.Show Full Screen Parts breakdownShow Full Screen

Parts breakdownShow Full Screen

Robust, efficient and consistent grinding with a gravity fed SKIOLD's DM6 Hammer Mill. Engineered for high-capacity size reduction of a wide range of materials, from grains and feedstuffs for feed or use as biomass.

SKIOLD ‘Gravity’ Hammer Mills allow raw material to fall throught the inlet into the grinding chamber. Here it is hit by the rotating hammers and thrown against the screen till reduced to a size that allows it to pass through the chosen hole size dimension . The SKIOLD DM range uses a traditional system with an inlet magnet, flail rotor with hammers and interchangeable screen sizes ranging from 1.0 – 16mm.

SKIOLD DM2 and DM3 Hammer Mills

SKIOLD DM-3 Hammer MillShow Full Screen

SKIOLD DM-3 Hammer MillShow Full Screen SKIOLD DM-3 Mill sucking from SiloShow Full Screen

SKIOLD DM-3 Mill sucking from SiloShow Full Screen Show Full Screen

Show Full Screen Show Full Screen

Show Full Screen

SKIOLD DM2, DM3 hammer mills are ideal for grinding of animal feed. Supplied with a built-in fan to carry raw and ground material throughout the system, it has the advantage of cooling meal in the process.

A simple but robust mill that can be fitted to most set ups:

- Grinds animal feed

- Capacities up to 1500 Kg an hour

- Conveying capacities up to 80 meters

- Comprehensive range of accessories

- simple maintenance

- Flexible application