Sipma Roller MillShow Full Screen

Sipma Roller MillShow Full Screen Magnet cartridge protects crusher mechanism from unwanted metal or stones.Show Full Screen

Magnet cartridge protects crusher mechanism from unwanted metal or stones.Show Full Screen Body design ensures tightness of the crusher and enables precise assembly of working elements.Show Full Screen

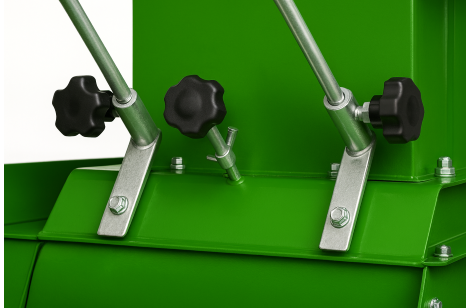

Body design ensures tightness of the crusher and enables precise assembly of working elements.Show Full Screen Grain dosing adjustment of charged grain to the working gap size.Show Full Screen

Grain dosing adjustment of charged grain to the working gap size.Show Full Screen V Belt SystemShow Full Screen

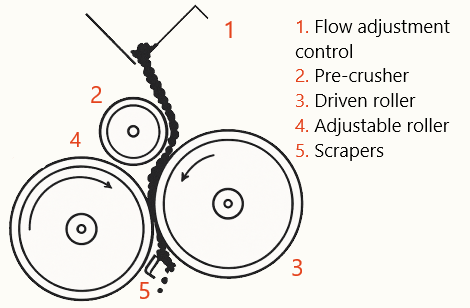

V Belt SystemShow Full Screen Three roller system pre-crushes feedShow Full Screen

Three roller system pre-crushes feedShow Full Screen Flow adjustment controlsShow Full Screen

Flow adjustment controlsShow Full Screen Grain before rolling with a Sipma millShow Full Screen

Grain before rolling with a Sipma millShow Full Screen Grain after rolling with Sipma millShow Full Screen

Grain after rolling with Sipma millShow Full Screen

Unlock Superior Feed Processing with Sipma Roller Mills

Roller mills offer a robust, efficient, and reliable way to process grains for your livestock. Engineered with precision, and built to last, they are the ideal solution for farmers seeking to optimize feed quality and reduce costs.

Experience the Sipma Advantage:

The Power of the Three-Roller System

The Sipma 7530 and Sipma 4030 mills both have the innovative three-roller system at their heart. This advanced design offers significant advantages over traditional two-roller mills:

- Increased Throughput: The three-roller configuration allows for a higher volume of grain to be processed in the same amount of time, boosting your efficiency.

- Improved Crushing Uniformity: By passing the grain through two distinct crushing stages, the three-roller system ensures a more consistent and uniform particle size. leading to better feed quality and digestibility.

- Reduced Stress on Components: The load is distributed more evenly across three rollers, leading to less wear and tear on the machine and extending its lifespan.

- Enhanced Control Over Particle Size: The adjustable gaps between the rollers provide greater control over the final fineness of the processed grain, allowing you to tailor the feed to the specific needs of your animals

Technical Details

- Enhanced Feed Digestibility: Precisely crushed grains improve nutrient absorption, leading to healthier animals and better feed conversion rates.

- Energy Efficiency: designed for optimal performance with lower energy consumption, saving money on operating costs.

- Versatile Grain Processing: Effectively process a wide range of grains, including barley, wheat, oats, beans and more.

- Durable and Reliable Construction: Built with high-quality materials and expert craftsmanship, Designed for years of dependable service.

- Reduced Feed Waste: Consistent crushing ensures less fine dust and more palatable feed, minimizing waste.

Both models are suitable for milling barley, oat, wheat, rye, bean, pea and leguminous plants, They allow for precise adjustment of the working port and have magnet cartridges to protect from metal entering the mill and causing damage.

Sipma 7530 |

Sipma 4030 |

|

| Engine Power | 7.5 kW | 4 kW (3.7 kW single phase available) |

| Capacity | Three tonne per hour | One tonne per hour |

| Width of Roller | 300 mm | 160 mm |

| Diameter of Roller | 290 mm | 290 mm |

| Drive Transmission | Transmission belts | Transmission belts |

| Legs (optional) | Standard (750 mm) | Standard (750 mm) |

| Length | 1200 mm | 1240 mm |

| Width | 780 mm | 620 mm |

| Height | 1800 mm | 2000 mm |

| Weight | 485 kg | 270 kg |

Invest in a Sipma Roller Mill and experience the difference in feed quality, efficiency, and long-term cost savings.