Recent Projects

Upgrade to Pig Farm Intake System in Lincolnshire

Danagri-3S recently completed a significant upgrade at a pig farm in Lincolnshire, installing a Jema Dry Pit intake system to replace an outdated setup that was struggling with water ingress and slow handling speeds. The previous installation had two key issues:

- Water ingress was causing operational delays and maintenance challenges.

- The elevator and conveyor capacity were insufficient for the farm’s growing requirements.

To resolve these, our team installed a Jema Dry Pit intake, designed to maintain high intake capacity while preventing water problems. The solution involved raising the concrete floor level beneath the pit by 1.5 metres, ensuring optimal drainage and protection against water ingress.

The new system includes:

- 60tph intake conveyor for faster unloading.

- Belt & bucket elevator for efficient vertical transport.

- Top conveyor feeding raw material directly into silos.

This modular design not only sped up intake but also reduced the need for extra trailers and drivers, saving time and costs. The suspended hopper design allowed easy servicing and kept the conveyor base clear of the floor, further minimizing moisture risks.

Fan & Heat Exchanger completed this Year in Cheshire

Danagri-3S recently completed an installation at a Cheshire farm, equipping a 500-tonne grain store with a modern floor aeration system. The project included drive-over laterals, a Lokke centrifugal fan, heat exchanger, concrete centre tunnel, and exhaust fans, all designed to deliver superior grain handling and storage performance.

The drive-over laterals provided easy access for adding and removing grain, making the shed highly versatile. When filled, the system ensured cereals could dry efficiently and kept in excellent condition by blowing air across the laterals. This airflow, powered by the Lokke centrifugal fan, now helps maintain grain quality, reduces moisture, and prevents spoilage.

The design included a central inspection trench, giving operators full control over which laterals carry air. This feature allows targeted drying and optimizes energy use, ensuring the process is both effective and economical.

When empty, the shed can be repurposed for other farm needs, such as storing vehicles or equipment, adding year-round value to the investment.

Danagri-Rekord Floor Store Stirrer Supplied to Customer in Cambridgeshire

A recent Danagri-3S installation in Cambridgeshire of a Rekord floor store stirrer has tackled persistent issues of damp grain. The customer had been struggling with uneven drying and cereals standing upright, with risks for mould growth, insect infestation, and even development of harmful mycotoxin, with damp pockets leading to heat build-up, spoilage, and significant financial loss.

The Rekord stirrer now continuously mixes the grain, breaking up damp spots and temperature layers. This even distribution allows air to flow uniformly through the crop, improving drying efficiency and preventing the formation of “hot spots”, helping maintain grain quality throughout storage.

Roller Mills

We have had an increase in enquiries for our range of roller mills in the last two months, with farms looking to improve feed quality, reduce waste, and streamline grain processing. Sipma mills meet these demands, producing consistent grain size that improves digestibility, and reduces waste. They also offer advantages over hammer mills, putting out less dust and heat, so preserving nutrients in the feed.

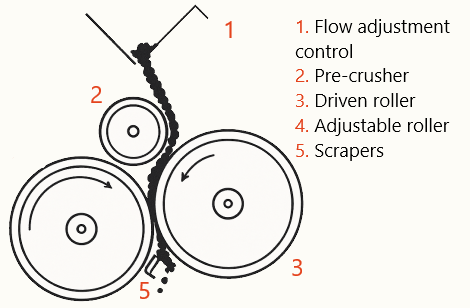

The SIPMA Roller Mill series includes models that use the three-roller system that incorporates a pre-crusher, giving them an edge over two roller competitors. Both models have a magnet cartridge for protection against metal contamination and controls for grain dosing.

- SIPMA 7030 – 7.5 kW power, up to three tonne/hour.

- SIPMA 4030 – Compact design, 4 kW power, one tonne/hour, option for single phase motor.

Click here to find out more or contact us to discuss.

Preharvest Grain Dryer Servicing

We are taking bookings for farms looking to arrange a pre-harvest service for mobile grain dryers. Experience proves this precaution reduces the risk of costly breakdowns, lowers energy consumption, shorten drying times, and minimises fire risks associated with dust buildup. A service also comes with an inspection report for compliance with the Trade Assurance Scheme for Combinable Crops (TASCC)

Book online here, or call 01746 762 777 and ask for Andrew Unitt.

Thank you

As we wrap up 2025, we want to thank all our customers for your continued support. From everyone at Danagri-3S, we wish you a very Merry Christmas and a Happy New Year. We look forward to working with you in 2026.