Originally developed for pig production, the Skiold Transpork system is a cable‑and‑disc dry feeding solution that is attracting interest for a range of industries. Danagri‑3S has recently installed, and had enquiries about the system from not only pig units, but also poultry operations, brewing facilities, and for handling materials such as grass seed and pellets.

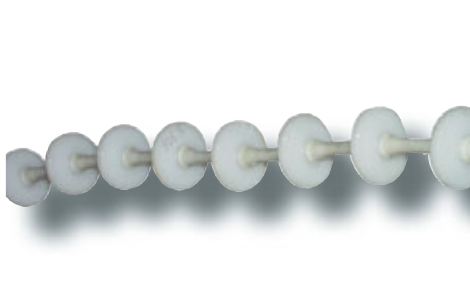

Skiold Transpork operates with pipes arranged in a circuit. Inside the pipe runs a cable fitted with evenly spaced discs that move material at capacities from 300 to 2,100 kg per hour — a significant increase compared with traditional dry feeding systems.

The cable is coated with a rubber alloy to create a neutral, non‑drying environment between the discs. This results in a strong yet supple chain that can navigate corners and drive units smoothly, while minimising wear and eliminating the risk of frayed material entering the feed.

Transpork corners are manufactured from hard‑wearing plastic and can be positioned horizontally, vertically, or on an incline. The overall system offers high capacity, flexible installation options, and proven reliability.

To find out more, please contact us at Danagri‑3S.