Hopper Silos / Hopper Tanks

Hopper silos and tanks are essential components of modern farm infrastructure, offering practical solutions for grain storage, feed management, and operational efficiency. Their unique design and functionality make them ideal for a wide range of agricultural applications.

Efficient Grain Unloading

The conical bottom allows gravity to complete grain clean-out with minimal residue. This leads to fast and easy unloading, without the need for mechanical sweepers, reducing labour costs and time spent on manual handling.

Improved Grain Quality

Smooth material flow prevents compaction and stagnation, maintaining grain integrity, reducing spoilage and the risk of mould. Extends storage life with effective ventilation and moisture control.

Versatile Storage Options

Hopper tanks are used for various purposes on farms, including:

- Wet bins for temporarily holding moist grain before drying.

- Load-out bins for easy transfer to transport vehicles.

- Feed bins for storing and dispensing livestock feed.

Space and Cost Efficiency

Hopper tanks are compact, so can be installed in tight spaces, the vertical design maximising storage capacity per square foot and reducing need for extensive ground preparation.

Automation and Integration

Modern hopper systems can be integrated with fertiliser distribution systems for precise nutrient application, tank hopper scales for accurate inventory and feed control.

Flexibility Across Farm Sizes

Suitable for small family farms or large commercial operations – available in sizes from 50 to 1600 tonnes capacity, with hopper angles ranging from 40° to 67° for different material flow needs.

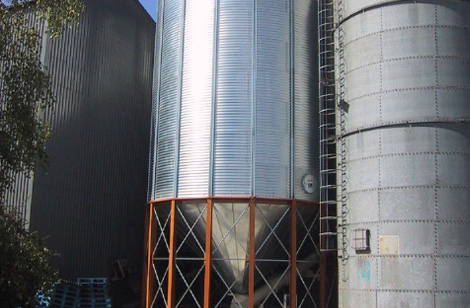

NCHT - Industrial Hopper Tank

36’ diameter GSI Hopper Silo – YorkshireShow Full Screen

36’ diameter GSI Hopper Silo – YorkshireShow Full Screen Hopper Silo legs and access ladderShow Full Screen

Hopper Silo legs and access ladderShow Full Screen Silos on commercial storeShow Full Screen

Silos on commercial storeShow Full Screen

- Designed for heavy use in mills, ports etc.

- Silos feature stiffened sidewalls

- 66” corrugated sheets

- Heavy duty I-beam legs, compression ring.

- Hopper angles of 40, 45 or 60 degrees

- Sizes range from 12’ to 36’ diameter,

- 50 – 1600 tonnes capacity

FCHT – Commercial Hopper Tank

30’ hopper silo – PowysShow Full Screen

30’ hopper silo – PowysShow Full Screen FCHT Hopper SilosShow Full Screen

FCHT Hopper SilosShow Full Screen Silo on sub-frameShow Full Screen

Silo on sub-frameShow Full Screen Rack & Pinion outletShow Full Screen

Rack & Pinion outletShow Full Screen

- Designed for use in mills & grain stores

- Silos feature stiffened sidewalls

- 4” corrugation sheets for cleaner out-loading

- Hip compression ring

- Hopper angle of 45 degrees

- Sizes range from 18’ to 24’ diameter,

- 90 – 400 tonnes capacity

GHT - Grain Hopper Tanks

Row of Silos at commercial store Show Full Screen

Row of Silos at commercial store Show Full Screen Silos with catwalk - HerefordshireShow Full Screen

Silos with catwalk - HerefordshireShow Full Screen Outlet to 6” auger - ScotlandShow Full Screen

Outlet to 6” auger - ScotlandShow Full Screen Silo with access ladder - ShropshireShow Full Screen

Silo with access ladder - ShropshireShow Full Screen

- Designed for farm use

- Mainly used as ‘wet’ storage

- Galvanized steel legs with braces

- Special ‘drip-lip’ to feed water away

- Hopper angle of 45 degrees

- Sizes range from 9’ to 21’ diameter

- 9 – 169 tonnes capacity

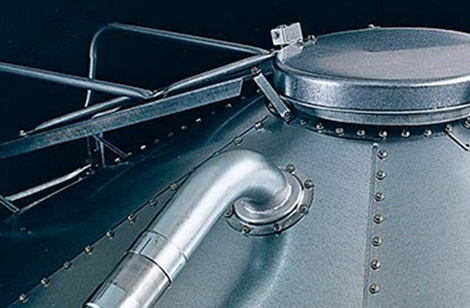

BFT - Bulk Feed Tanks

Feed SilosShow Full Screen

Feed SilosShow Full Screen Blower inletShow Full Screen

Blower inletShow Full Screen Feed silos with flex augersShow Full Screen

Feed silos with flex augersShow Full Screen Feed silos with flex augersShow Full Screen

Feed silos with flex augersShow Full Screen

- To store and protect feed or pellets

- Sealed roof

- Optional pneumatic inlet

- Hopper angle is 60 degrees

- Sizes range from 6’ to 15’ diameter

- 50 – 63 tonnes capacity

- 7’ dia. silos available with 67 degree hoppers