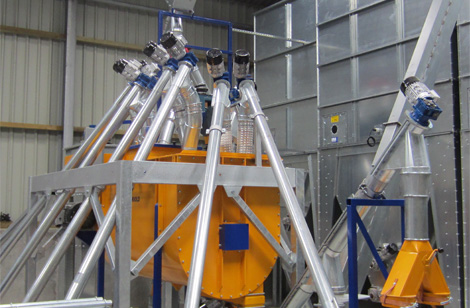

SKIOLD 3 stage mixer plantShow Full Screen

SKIOLD 3 stage mixer plantShow Full Screen SKIOLD 2 stage mixer with pre-binShow Full Screen

SKIOLD 2 stage mixer with pre-binShow Full Screen SKIOLD single stage horizontal mixerShow Full Screen

SKIOLD single stage horizontal mixerShow Full Screen 3 stage mixerShow Full Screen

3 stage mixerShow Full Screen

- Three models available : one, two & three stage

- Batch sizes of up to 1000kg

- Designed for computer controlled feed mills

- High mixing accuracy 1:100000

- Special ribbon mixer auger

- Oil & Molasses additions of up to 10%

- Outputs from 1.5 – 8 tonnes per hour

- Cylindrical mixing trough for optimum emptying

- Solid construction with heavy duty gearbox drive

- Single stage mixers for up to 2.5 tonne per hour

- Two stage mixers for up to 6 tonne per hour

- Three stage mixer for up to 8 tonne per hour

The SKIOLD H-2000 mixer is a batch mixer suitable for mixing almost any kind of meal or granulated raw material with very high accuracy. During the mixing process, which takes 4-12 minutes, it is possible to add fluid raw materials like fat, oil, molasses as well as up to 50% of corncob maize (CCM). The SKIOLD H-mixer is made with an open double auger and the mixing trough is cylindrical shaped just like the auger.

This secures not only a homogeneous mixing, but also an optimum emptying of the mixer. The special construction of the open double auger has the effect that the material furthest out in the mixer is pulled in one direction, whereas the smaller central auger pulls the material in the opposite direction. This mixing method is very effective and gives a very homogeneous feed mixture.

By adding a pre-bin to the top of the mixer, we make a two stage unit which allows you to load and weigh in another batch whilst the main section is mixing a batch

By adding a discharge bin under the mixer section, this further speeds up the mixing process by letting augers take away one batch whilst the mixer section deals with the next batch.