Elevators & Conveyors

SKIOLD have a comprehensive range of Intakes, elevators and conveyors suitable for the transport of grain, granulates and feed products, some of these have been designed specifically for use in feed mills. The machines heavy duty and are suitable for farm or large commercial operations. All machines are galvanized and of modular construction for ease of transport and assembly plus all are driven by ATEX 22 rated gear motors.

Intakes

X

SKIOLD Intake pit Show Full Screen

SKIOLD Intake pit Show Full Screen Intake with dust extraction systemShow Full Screen

Intake with dust extraction systemShow Full Screen Many sizes for farm or CommercialShow Full Screen

Many sizes for farm or CommercialShow Full Screen Walk over or drive over versionsShow Full Screen

Walk over or drive over versionsShow Full Screen Walk over pit, cleaner & elevatorShow Full Screen

Walk over pit, cleaner & elevatorShow Full Screen

- Bespoke design for each site

- Modular build

- Walk over or drive over versions

- Bolt together construction

- Avoids water in intake pit

- Depth and length to suit each site

- Fits SKIOLD intake conveyors

- Optional dust collection systems

Conveyors for transport and intake

X

SKIOLD chain & flight conveyors Show Full Screen

SKIOLD chain & flight conveyors Show Full Screen Intermediate outletShow Full Screen

Intermediate outletShow Full Screen Many sizes for farm or CommercialShow Full Screen

Many sizes for farm or CommercialShow Full Screen SKIOLD chain & flight conveyorsShow Full Screen

SKIOLD chain & flight conveyorsShow Full Screen

- Capacities up to 475 m³/hour

- Heavy duty, galvanized construction

- Shaft mounted helical geared motor

- Combined drive/tension section

- Reversible drive options

- 4mm base plate as standard, optional 10mm

- Large range of accessories

- ATEX zone 22 approved

'Clean' Conveyor for transport and intake

- Round bottom for optimized self-emptying

- Capacity up to 29 m3/hour

- Conveying of grain, minerals, granulates, pellets and meal products

- Strong galvanized or stainless steel construction

- Shaft mounted helical geared motor

- Combined tension and drive unit

- Fully U-shaped turn end

- PEHD scrapers on chain

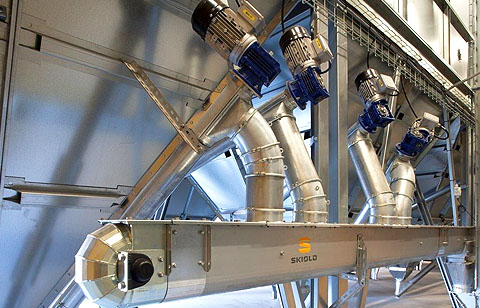

Belt & Bucket Elevators

X

SKIOLD Belt & Bucket ElevatorsShow Full Screen

SKIOLD Belt & Bucket ElevatorsShow Full Screen Elevators with ladders and service platformsShow Full Screen

Elevators with ladders and service platformsShow Full Screen SKIOLD Service PlatformsShow Full Screen

SKIOLD Service PlatformsShow Full Screen SKIOLD Elevators in millShow Full Screen

SKIOLD Elevators in millShow Full Screen Elevators, ladders and platformsShow Full Screen

Elevators, ladders and platformsShow Full Screen

- Vertical conveying of grain, granulates and meal

- Six different models

- Capacity from 14 to 545 m³/hour

- Heights up to 40m

- Shaft mounted ATEX gear motor

- Anti-static and oil resistant belt

- Backstop

- Wide range of accessories