Control Panels & Automation

Danagri-3s supply a choice of two control systems manufactured by Skiold for the automated control of your feed mill, the Flexmix and Flexmix Pro. The system as the name suggests allows for alteration and extension at a later date and includes all electrical components for the operation of the feed mill.

Flexmix

X

Flexmix panel frontShow Full Screen

Flexmix panel frontShow Full Screen Panel and flow diagramShow Full Screen

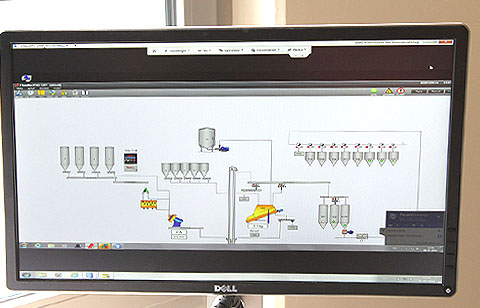

Panel and flow diagramShow Full Screen Flow diagram on computer screenShow Full Screen

Flow diagram on computer screenShow Full Screen Panel can be sited remotelyShow Full Screen

Panel can be sited remotelyShow Full Screen

- Tailored to individual needs

- Handles 3 separate weighing systems

- Flowdiagram display with manual buttons

- 50 recipes and 50 raw materials

- Production history and stock control

- Connect to PC and printer.

Flexmix Pro

X

Flexmix pro panelShow Full Screen

Flexmix pro panelShow Full Screen Flow diagram on computer screensShow Full Screen

Flow diagram on computer screensShow Full Screen Flexmix pro panelShow Full Screen

Flexmix pro panelShow Full Screen Flow diagram on computer screensShow Full Screen

Flow diagram on computer screensShow Full Screen

- Tailored to individual needs

- Handles 10 separate weighing systems

- PC control with graphic display

- Unlimited recipes and raw materials

- Production overview and reports

- Traceability of components.