Flour Milling

Danagri supply the world renowned range of ENGSKO Flour Mills and Flour milling plants for both white flour and wholemeal flour. Whilst the original design of the machines was for flour, our mill are also used for many other products like Coffee, Spice, Maize, Rice etc.

Flour Mills and Flour milling plants

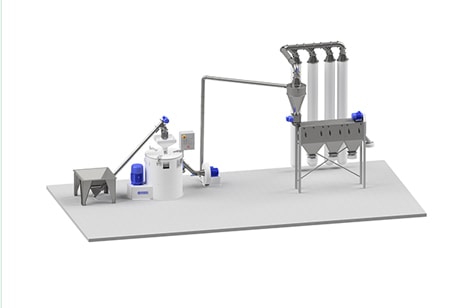

Caption Flour milling system with stone mill and rotary sifterShow Full Screen

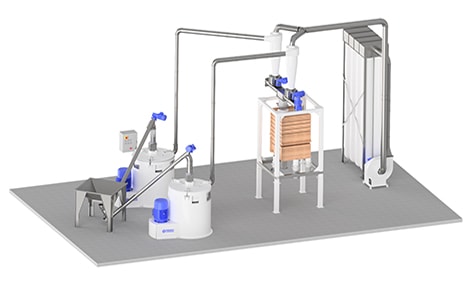

Caption Flour milling system with stone mill and rotary sifterShow Full Screen Caption Flour milling system with 2x stone mills and plan sifterShow Full Screen

Caption Flour milling system with 2x stone mills and plan sifterShow Full Screen Caption System with 4x stone mills, plan sifter & filterShow Full Screen

Caption System with 4x stone mills, plan sifter & filterShow Full Screen

There is nothing better than organic and sustainable products made on a Stone Grinding Mill where all essential vitamins, proteins, minerals and fibers are kept and utilized. ENGSKO specialize in these solutions, where the organic and sustainable approach is the primary focus.

The ENGSKO Mill Stones are at the heart of the system and consist of high-quality materials such as flint and emery.

The ENGSKO Grind-master Stone Grinding Mill is the essential machine in our plants giving a high quality stone ground flour.

The ENGSKO MHA Discmill is a higher capacity mill and can be used to break the grain before grinding to fine flour on the Grind-master Stone Mill, thereby reaching a higher capacity

Our Grinding Mill Plant Technology can handle an hourly intake capacity from 80 kg up to 2.000 kg of fine ground product such as Wheat, Maize, Quinoa, Sorghum, Spices, Coffee etc. We can also offer and design larger plants upon specific request.

We also offer a complete range of other machines and accessories to complete the plant like Mixers, Sifters, Conveyors, Packaging equipment etc.

With an ENGSKO traditional Stone Grinding Mill Plant, you will receive several advantages, both product and business wise:

- Healthy Nutrition & Diet

- Value Adding to your business

- 100% utilization of your product

- Fast Return on Investment

- Low Start-up costs for Sustainable & Organic Milling

From Organic Coffee at your favourite Coffee Shop to Nutritious Biscuits handed out in Refugee Camps, ENGSKO has been involved both as supplier and advisor in many projects. Their list of satisfied customers is long and both Stand-Alone Grinding Mills & Mill Stones as well as Grinding Mill Plants have been installed and commissioned throughout the world to both private customers and various organizations.