MTX Multimix Mixers

The Cormall range of stationary, electric drive MTX Multimix Mixers were originally designed as diet mixers for silage and cattle feed but over the years we have sold them for use with many materials like chopped straw, meals, compost, potato waste, sludge etc.. Whether using the Cormall mixer as a diet mixer or a straw bale shredder there is no comparison for its reliability and durability.

With the mixer housing twin augers to keep material moving, loadcells/weight computer for automated loading and a hydraulic door to control the emptying, material is processed, stored and delivered with ease.

These mixers come in sizes from 10 to 50m³ and various motor sizes to suit any application. The mixers can come with a sealed roof for use as a buffer silo or with an open top for loading with a teleporter, forklift or overhead crane. We can provide remote weight displays and read outs for data collections and manufacture bespoke outlet transitions to fill to any subsequent equipment.

MTX-H straw shredding MixerShow Full Screen

MTX-H straw shredding MixerShow Full Screen MTX Biomass mixer filled by craneShow Full Screen

MTX Biomass mixer filled by craneShow Full Screen MTX Diet mixer Show Full Screen

MTX Diet mixer Show Full Screen MTX mixers used for horse feedShow Full Screen

MTX mixers used for horse feedShow Full Screen MTX mixer with roof used as milled straw buffer hopperShow Full Screen

MTX mixer with roof used as milled straw buffer hopperShow Full Screen SBB pre shredder for straw in MTX mixerShow Full Screen

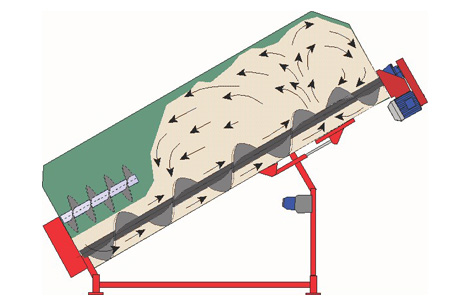

SBB pre shredder for straw in MTX mixerShow Full Screen MTX mixing principle with pre-shredderShow Full Screen

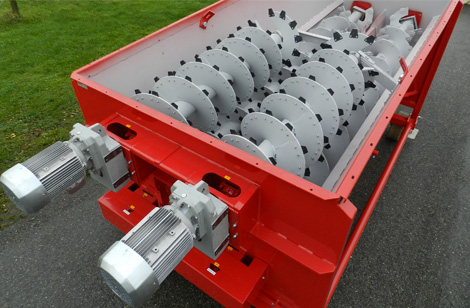

MTX mixing principle with pre-shredderShow Full Screen 800mm diameter augers with cutter bladesShow Full Screen

800mm diameter augers with cutter bladesShow Full Screen

Cormall MTX features:

- 10, 12, 15, 18, 22, 30, 42 or 50m³ capacities

- Proven twin auger mixing concept

- Low fill height

- Optional cutter blades on auger

- 10mm steel plate body

- 15mm thick auger flights

- Optional Stainless steel versions

- Excellent for Biomass